July 2022 - January 2023 • Freight Forwarding App

Background

Efficient freight movement is central to Flexport's vision as a comprehensive logistics platform. With limited functionalities in our Freight Forwarding App, our operations teams have struggled to effectively manage the growing volume of shipments and complex workflows. This has led directly to decreased operational efficiency, increased reliance on external tools, and eroded customer trust due to inaccurate or delayed shipments.

The Freight Forwarding App originally designed as a basic task management tool, has failed to scale with Flexport's rapid growth. Operations managers lack visibility into team performance, while they grapple with information overload and inadequate prioritization mechanisms. The absence of crucial features has forced many to revert to spreadsheets, resulting in decentralized data and compromised accuracy.

These challenges not only hinder internal operations but also impact our ability to provide timely and accurate shipment information to customers. The need for a more robust features has become critical to maintain Flexport's operational excellence and sustain customer satisfaction in an increasingly competitive market.

solution

To address these challenges, we're introducing TeamView, a unified platform for end-to-end shipment visibility. TeamView is designed to empower managers with comprehensive oversight and actionable insights, significantly enhancing operational efficiency and decision-making capabilities. By optimizing visibility and providing real-time, actionable insights, it aims to streamline workflows, reduce guesswork, and ultimately improve the efficiency of moving shipments. By centralizing data and enhancing visibility, TeamView aims to restore operational excellence and strengthen customer trust in Flexport's logistics capabilities.

6.5%

Increase

Shipment on-time performance improvements

250+

Hrs saved

In operator time, spent triaging shipment issues

15%

Increase

CSAT score improvements over last year

Why is shipment tracking so frustrating today?

Despite shipments being the cornerstone of Flexport's business, the tools and practices used to monitor, manage, and optimize freight movement are outdated and inefficient. Operators are forced to navigate through a maze of disconnected data, leading to missed deadlines and frustrated customers.

Too Much Noise, Too Little Signal

Information overload causes managers to lack clear visibility into team activities and shipment statuses. This blindspot makes it difficult to track individual responsibilities, monitor progress, and identify bottlenecks. As a result, accountability suffers and team efficiency decreases.

Who's Doing What, When, and Why?

The current experience lacks effective mechanisms to prioritize tasks or track work progress within shipments. Without clear indicators of task importance or impending deadlines, operators are left guessing which actions to tackle first.

Regression to old tools

Frustrated by inadequate systems, many have reverted to spreadsheets for tracking and management. This reliance on manual, disconnected tools leads to data inconsistencies, lack of real-time updates, and increased errors. It's a step backward for a software forward company like Flexport.

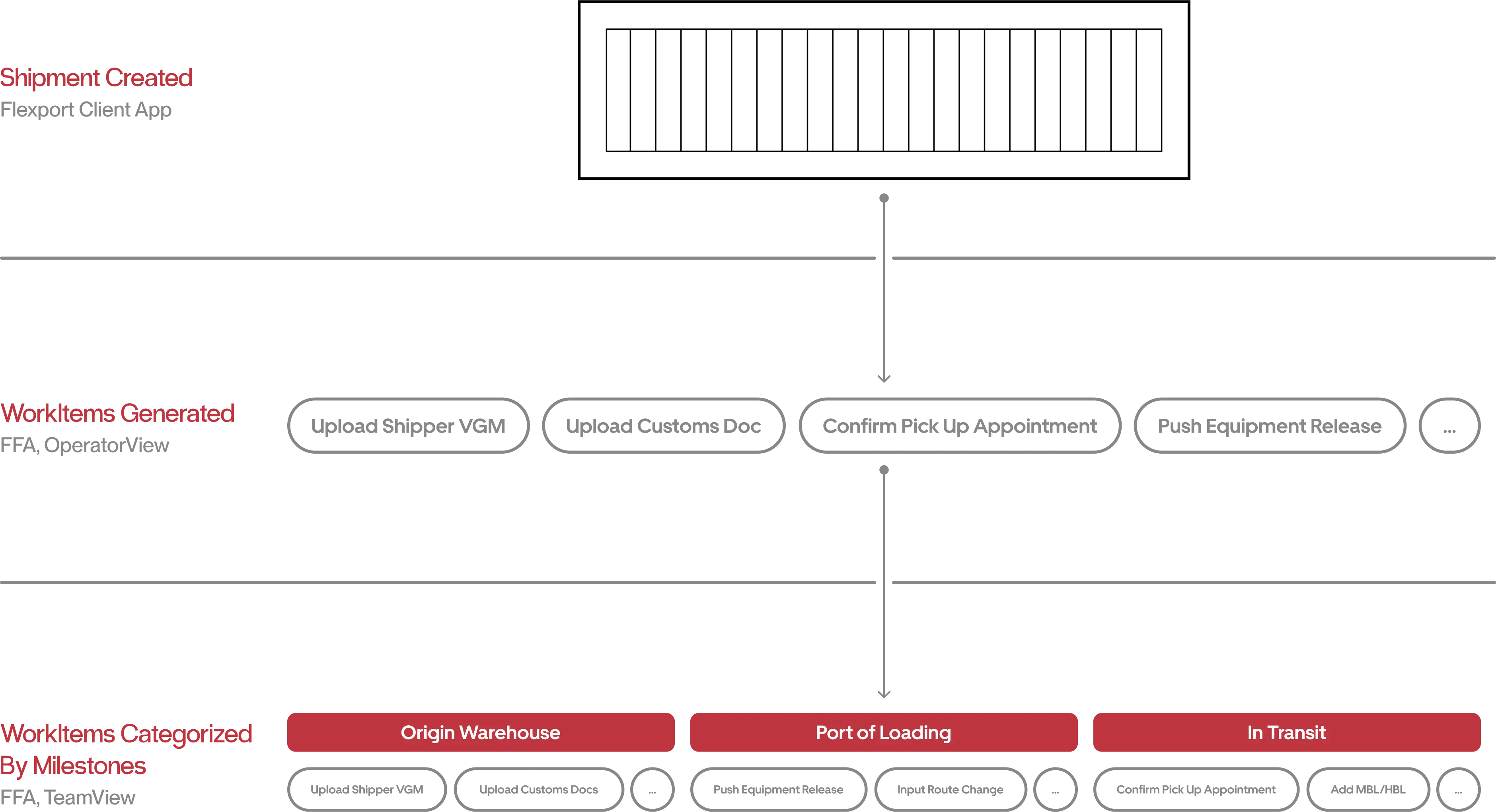

A Milestone-Based Approach

In developing TeamView, we collaborated closely with engineering to create a scalable architecture that mirrors the real-world journey of shipments. Our approach was inspired by how freight actually moves: through distinct milestones such as Port of Loading, Transit, and Destination Warehouse.

We structured TeamView to visualize shipments as they exist in reality, categorizing work items by these key milestones. This intuitive organization allows operations managers to focus on the specific legs of the journey relevant to their teams, providing a natural and efficient way to track progress. This real-world-based design not only addresses current operational challenges but also establishes a flexible foundation that can evolve with Flexport's growing needs, minimizing future technical debt.

Focusing on the fundamentals

I worked closely with product managers and engineers to construct logistics visualizations and action-items all with the goal of providing the user with deep insight into their global supply chain. I sketched explored and brainstormed new possibilities that goes beyond what we were familiar with. I created mid-fidelity wireframes and prototypes to test rigorously with our operators. The outcome was to develop two distinct views: a shipment timeline and a shipment list view.

Milestone-Segmented Shipment List

The TeamView is fundamentally a shipment list, we decided to go with this approach because it aligns with operators' existing mental models. We surface work item status segmented by shipment milestones, providing a familiar yet enhanced view of operations. We also implemented role-based default filters. These pre-applied filters eliminate noise by showing only the most relevant information.

Get the full picture with Shipment Timeline

For the first time ever, we're introducing a shipment timeline that visualizes the entire journey. Managers can now see past, present, and future legs of shipments, including those outside their team's direct responsibility, enabling quick cross-team issue triage. This at-a-glance overview of responsibilities, progress, and SLAs allows Managers to shift focus to the relevant legs of the journey. TeamView automatically highlights crucial milestones that could risk shipments or cause dependencies, speeding up problem resolution by clearly showing property relationships.

Performance management built in

Managers now can get real-time visibility into their team's workflow and view any active milestones, eliminating guesswork and enhancing coordination. We've integrated performance management capabilities, allowing managers to set On-Time Performance (OTP) metrics that connect directly to OperatorView. This integration enables immediate assessment of team performance without leaving the TeamView interface.

Compliance & Container level info On Demand

Our usability testing revealed that managers often had to navigate away from their main workflow to access essential information like dangerous goods classification and container statuses. This constant context-switching contributed to inefficiency and potential oversight of crucial details.

To address this, we integrated dynamic, on-hover tooltips into the shipment list. These tooltips provide instant access to vital information such as dangerous goods classification, cargo details, and comprehensive status context. We also included container numbers and their statuses, allowing managers to triage issues at the container level without leaving their current view.

Dynamic filtering and personalized views

To combat information overload, we introduced an all-new filter system that is consistently visible within the header and intelligently surfaces properties most frequently used by each user, learning from their behavior to provide increasingly relevant options. For more detailed analysis, users can access advanced filters, allowing for granular control over the displayed data.

Additionally, we also added the ability to save different instances of customized views, eliminating the need to repeatedly apply filters and sorts. This directly addresses the previous pain point of bookmarking individual links, streamlining workflow, and enhancing productivity.

outcomes

TeamView was launched in the November of 2022 to Flex-Go Operators and Import Partners and has significantly improved our operations management process. We achieved a 6.5% increase in shipment on-time performance and saved over 250 hours previously spent triaging issues. These tangible improvements directly enhance customer satisfaction and operational efficiency.

This project was my first time tackling an initiative of this scale independently. I gained invaluable experience in managing large-scale projects, balancing stakeholder needs, and driving iterative product development. The process sharpened my skills in cross-functional communication and reinforced the value of challenging the status quo. Working alongside a world-class team to elevate our product has been both humbling and inspiring. This experience accelerated my growth as a product designer, equipping me with the confidence to tackle complex challenges in the future.

It’s so much better compared to [Core] in keeping track of the work that’s going on. Helps saves time and enable our Mekong team to focus.

John Tai, Import Partner Supervisor

The MWI status makes so much sense and the table so much more useful as a team lead. I also like that its very easy to use because it looks similar to the old shipment list in [Core].

Srivikam Kopar, Flex-Go Ocean Manager

Honestly, I really love this new take on tracking shipments, we’ve been using spreadsheets for too long, glad to have this new version to look forward to.

Min Jae, EMEA Air Console Team Lead

Credits

It’s a huge privilege to have ownership over such a critical project and while I’m extremely proud of my role, it takes an entire village to get us across the line. Massive thanks to my key collaborators and many others. Eternally grateful to Dom and Alex for entrusting this fresh grad with such a pivotal feature to work on right out of college.

Christopher Sim

Design Lead

JJ Wang

Engineering Lead

Monti Thompson

UX Research Lead

Sangeetha Sitaraman

Product Lead